Services

Digital Management

Through a holistic approach we ensure implementation of a value-based digital transformation strategy that yields results now and in the future.

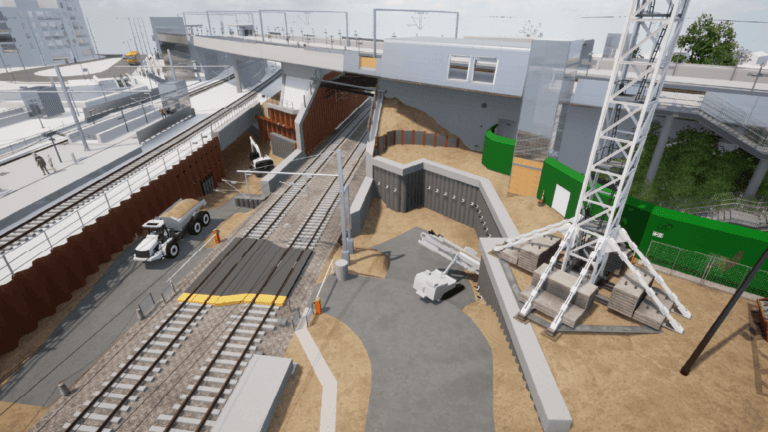

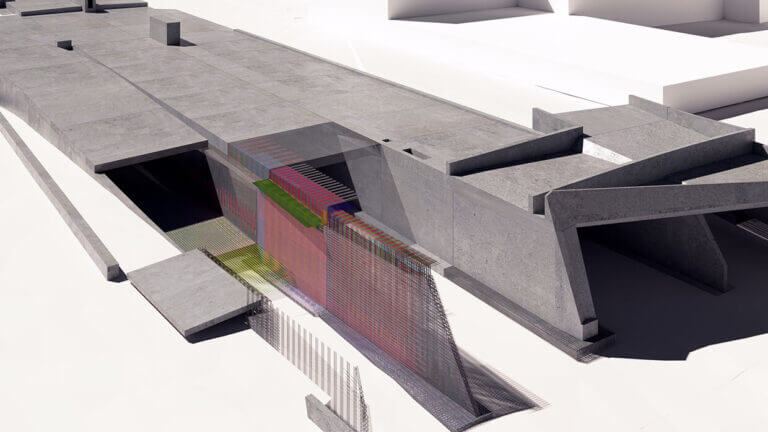

Virtual Design & Construction

Let us give you a head start and move forward with VDC technology. We ensure your projects are delivered on time, of the right quality and with optimized use of resources.

Digital Solutions

We build innovative digital solutions to provide our colleagues and clients with cutting-edge technology that utilizes resources more effectively through intuitive and collaborative use of digital tools.